This page was originally intended for describing rolled candles made by myself, but as I am no longer fit enough to pursue such activities, I include the details of the process in order that you can make a better quality job for yourselves.

These candles are rolled at a temperature that maintains a high plasticity in the wax. This gives a high consistency of burn, but a slightly smaller diameter, owing to the tighter and more consistent rolling that can be achieved at the higher temperature. (The amount of wax is greater than you may think, as the air spaces within the structure are much less than some candles manufactured by others.)

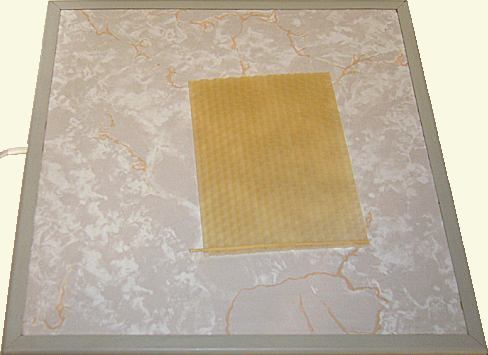

This elevated temperature is provided using a 350 mm square heating pad (30w) that was originally designed for warming four Demi-Johns containing wine must during the process of home brewing. The pad provides a gentle heat and locally increases the temperature of the foundation during the rolling process, making the wax more pliable and more easily worked. I have another heated pad that is 350 mm x 180 mm (20w) that is intended to accept two Demi-Johns and this can be used to pre-warm a stack of foundation sheets in order to further speed up the production process, however, the bottom sheet of the stack can become too soft if left too long, but you can overcome this by raising the stack of sheets on a type of wire grid that is sold for cooling cakes that have just been removed from the oven.

The warm pliable sheets increase the ease and speed that the candles can be made, which in turn increases productivity and maintains an even quality to the rolling process.

As with any other handicraft, there is a degree of skill involved in rolling the candles evenly and consistently, however the skill is soon acquired and your speed of production will rise. Do not be put off by a few attepts that go wrong or look ugly, you can burn these yourself and have a laugh at your handiwork. If it is something that you will do on an infrequent basis, perhaps once a year, then there will be a re-learning phase at the beginning of each session.

The sizes I have used are based on B.S. deep and shallow, subdivisions and multiples thereof, because that is what I have always had available or made for myself. Other sizes are available and highly coloured sheets of foundation are also to be had from the beekeeping supply trade. You can dye batches of liquid wax and make your own coloured sheets, but be aware that your homemade dyed wax may not be as stable in colour as the commercially produced coloured sheets.

Apart from foundation, I have also rolled plain wax sheets that have been formed in the same way as the sheets for the Herring Process, but I found the resulting candles rather un-interesting although they were very functional. There may be ways of utilising plain sheets to form a core for candles that require more than one sheet with the outermost layer being foundation, but I have not tried this method for myself.

Trimming the top edge of the sheet at slight angle (shownby the red line on the drawing) will cause the tip of the resultingcandle to be of conical form. The wick needs to be at the tallest part of the sheet.

Wick Selection

| Candle Description | Weight gms | Height mm | Width mm | Burn Time | Code |

|---|---|---|---|---|---|

| Rolled Candle | 16 | 127 | 17 | 2 hr 20 min | S/2V |

| Rolled Candle | 20 | 75 | 24 | 1 hr 12 min | D-S |

| Rolled Candle | 26 | 101 | 24 | 1 hr 49 min | D/2H |

| Rolled Candle | 31 | 127 | 24 | 2 hr 35 min | S |

| Rolled Candle | 51 | 203 | 24 | 3 hr 41 min | D |

| Rolled Candle | 62 | 127 | 38 | 5 hr 12 min | 2S |

| Rolled Candle | 102 | 203 | 38 | 8 hr 20 mon | 2D |

The codes are explained as follows...

S/2V is a BS shallow sheet cut to half length, D-S is what is left when a BS deep sheet is trimmed to shallow height, D/2H is a BS deep sheet cut in half lengthwise, S and D are single sheets of shallow and deep respectively, finally 2S and 2D are two full sheets of shallow and deep.

The burn times given were for a sample set of candles that might not give the same timings as your own versions, owing to different tightness of roll and wick choice. Perform such burn tests in a draught free environment.

The three candles shown at right are from left to right... 2S, S and S/2V , the coarse angular surface of the smallest diameter candle is caused by using drone foundation, which in small diameter candles bestowes quite a striking appearance.

The type S/2V candle represents very good value for money as the brightness of light and burn time is greater than the other types when the weight of wax is taken into account.

Dave Cushman.

Page created pre-2011

Page updated 30/12/2022